Using CAST Pedestrian to create more efficient Vaccination Centers

Health Care Simulation Project

While working together with various companies and stakeholders, ARC has used its pedestrian flow and logistics software to simulate the processes in a vaccination center. The experts believe that efficiency gains in the double-digit percentage range are possible with optimal planning. In this way, more citizens could receive the vaccine in a shorter time and the possible risk of infection in the vaccination center should decrease.

Vaccinating up to 80 million German citizens against Covid-19 is a logistical challenge. Computer programs normally used to simulate handling processes in airports could help make vaccination procedures run more smoothly. “We have run through the processes in a vaccination center using software we developed,” explains Michael Laubrock, managing partner at ARC. “Such simulations can help make processes much more efficient. Experience shows that improvements in the double-digit percentage range are possible with this methodology.”

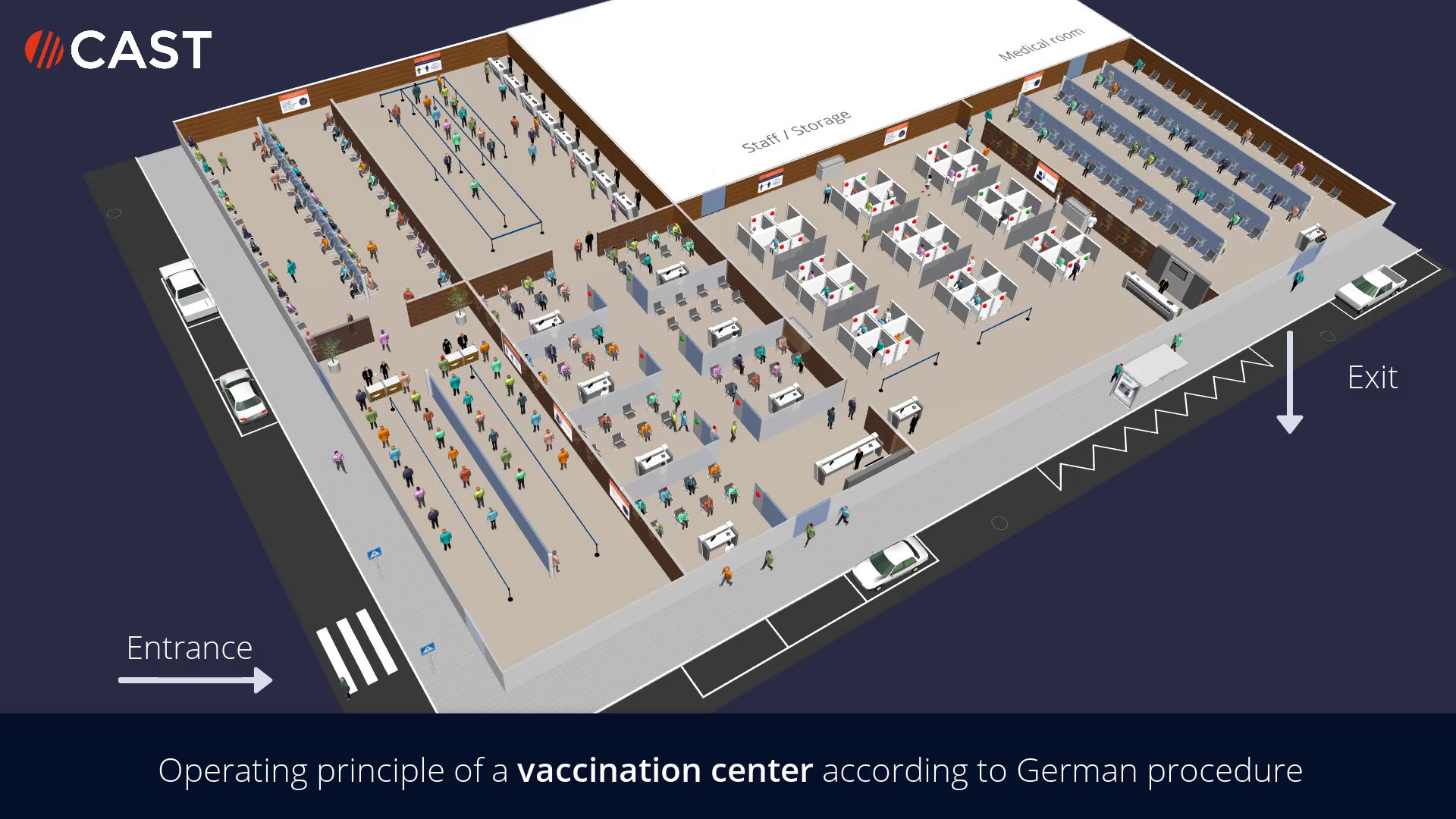

Similar to passenger check-in at the airport, various processes intertwine during vaccination: citizens must present their registration and are registered; they are informed about the procedure and any consequences; a temperature check may be performed to rule out existing infections; after the vaccine has been administered, they are observed for a while because of any allergic reactions. Good planning of spatial and personnel resources can prevent one of these steps from becoming a bottleneck that slows down the entire process chain.

Services provided

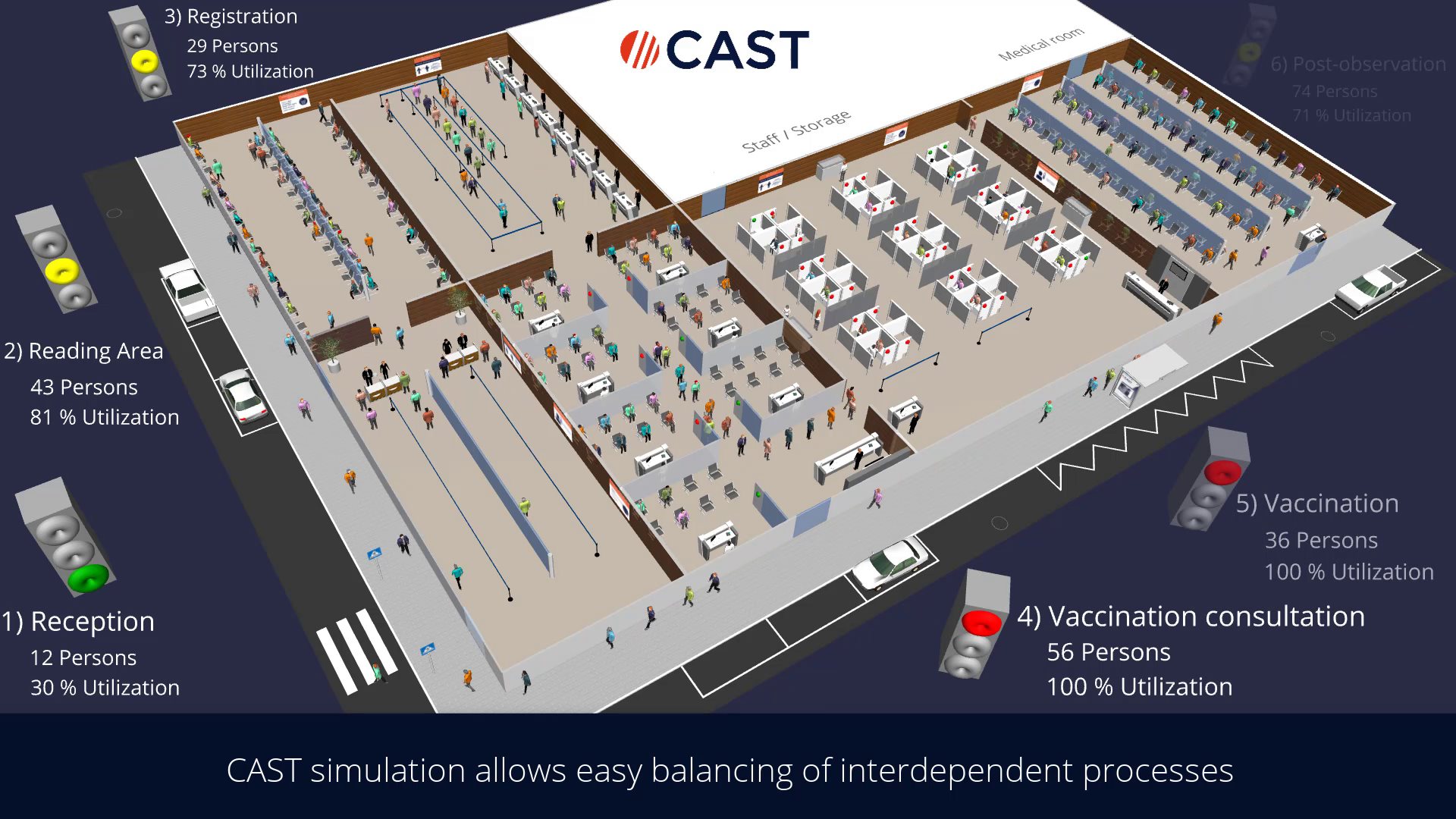

ARC simulates this chain with a so-called multi-agent system. To a certain extent, each person willing to be vaccinated acts for himself. In the process, he also interacts with the other “agents” in the microcosm of the vaccination center: he pays attention to distance, looks for the registration desk with the shortest queue, and at the same time tries to avoid unnecessary paths. The whole thing somehow represents an improvisational theater, in which the actors initially only know what goals they are supposed to pursue. The play develops from this only in interaction with the other performers; there is no fixed script. “In this way, we can see, for example, where things are jammed and what measures can be taken to get those present through more quickly,” explains Laubrock.

The model is created and simulated using the CAST software developed and distributed by ARC. In the model, all processes in the specific vaccination center are first defined and provided with realistic parameters. These include, in particular, the number of employees and stations used, their process times, spatial relationships or space requirements. In different scenarios, it is possible to check which adjustments and improvements are necessary and sensible in order to optimize operations, reduce the length of stay (and thus also the possible risk of infection of those willing to be vaccinated) and vaccinate more people in a shorter time.

Results and benefit

This new simulation approach revealed many new insights. In particular, it was possible not only to clearly confirm optimization potentials but also to quantify them for a solid decision making process.